Informationen zu Barry Wehmiller: Unterschied zwischen den Versionen

Rb (Diskussion | Beiträge) |

Rb (Diskussion | Beiträge) |

||

| Zeile 1: | Zeile 1: | ||

| + | '''Barry-Wehmiller History'''<br> | ||

| + | Quelle: https://www.barrywehmiller.com/story/history 2021<br> | ||

| + | '''1885'''<br> | ||

| + | Thomas J. Barry becomes half owner of a small millwright and general repair shop in the south part of St. Louis, Missouri (USA).<br> | ||

| + | '''1888''' | ||

| + | Barry opens a machine shop at 21st and Walnut streets, in St. Louis, Missouri (USA), to provide conveying and transportation equipment to malt houses. At this time, St. Louis was third in the nation for beer production—Anheuser-Busch alone sold 500,000-plus barrels of beer.<br> | ||

| + | '''1894'''<br> | ||

| + | Alfred Wehmiller, Barry’s brother-in-law, joins the millwright business as a draftsman. <br> | ||

| + | '''1897'''<br> | ||

| + | The Barry-Wehmiller Machinery Company is incorporated; with Barry as president and Wehmiller as secretary.<br> | ||

| + | '''1901'''<br> | ||

| + | The company designs and erects its first continuous basket pasteurizer, an economical machine that totally submerged refillable bottles. A soaking machine also is developed to fill and empty bottles of various solutions.<br> | ||

| + | From a Catalog: "Our soaking machines were the first ever built in which the tank was divided up into compartments or sections by transverse partitions, and in which the general direction of travel of the bottles was vertical instead of horizontal."<br> | ||

| + | '''1903'''<br> | ||

| + | Barry dies, and Wehmiller becomes president and treasurer.<br> | ||

| + | '''1913'''<br> | ||

| + | Barry-Wehmiller builds a new plant at 4660 West Florissant Avenue in St. Louis, Missouri (USA), with strategic access to railroads, moving from 21st and Walnut streets, which had housed the company since 1888. | ||

| + | From a Pamphlet: “The location affords unsurpassed railroad connections for the plant, which is supplied with three separate private switches for the transportation of all raw and finished products to and from the different buildings."<br> | ||

| + | {| class="galleryTable noFloat" | ||

| + | | [[File:1913_Annonce_BW_BJ_1.jpg|200px|thumb|left|Western Brewer 45/1915.<br> | ||

| + | Quelle:http:\\books.google.com]] | ||

| + | | [[File:1915_Annonce_BW_BJ_2.jpg|195px|thumb|left|Western Brewer 45/1915.<br> | ||

| + | Quelle:http:\\books.google.com]] | ||

| + | |} | ||

| + | |||

| + | |||

| + | |||

| + | |||

{| class="galleryTable noFloat" | {| class="galleryTable noFloat" | ||

Version vom 14. September 2021, 20:44 Uhr

Barry-Wehmiller History

Quelle: https://www.barrywehmiller.com/story/history 2021

1885

Thomas J. Barry becomes half owner of a small millwright and general repair shop in the south part of St. Louis, Missouri (USA).

1888

Barry opens a machine shop at 21st and Walnut streets, in St. Louis, Missouri (USA), to provide conveying and transportation equipment to malt houses. At this time, St. Louis was third in the nation for beer production—Anheuser-Busch alone sold 500,000-plus barrels of beer.

1894

Alfred Wehmiller, Barry’s brother-in-law, joins the millwright business as a draftsman.

1897

The Barry-Wehmiller Machinery Company is incorporated; with Barry as president and Wehmiller as secretary.

1901

The company designs and erects its first continuous basket pasteurizer, an economical machine that totally submerged refillable bottles. A soaking machine also is developed to fill and empty bottles of various solutions.

From a Catalog: "Our soaking machines were the first ever built in which the tank was divided up into compartments or sections by transverse partitions, and in which the general direction of travel of the bottles was vertical instead of horizontal."

1903

Barry dies, and Wehmiller becomes president and treasurer.

1913

Barry-Wehmiller builds a new plant at 4660 West Florissant Avenue in St. Louis, Missouri (USA), with strategic access to railroads, moving from 21st and Walnut streets, which had housed the company since 1888.

From a Pamphlet: “The location affords unsurpassed railroad connections for the plant, which is supplied with three separate private switches for the transportation of all raw and finished products to and from the different buildings."

| Datei:1913 Annonce BW BJ 1.jpg Western Brewer 45/1915. Quelle:http:\\books.google.com |

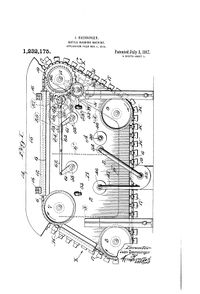

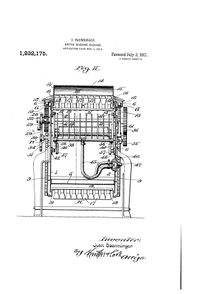

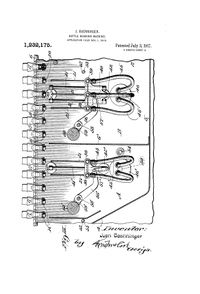

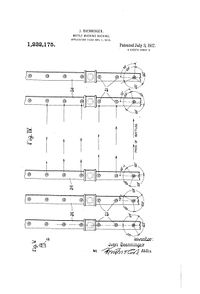

1917 US Patent 1 232 175